Specs at a glance

-

Max. measurement error

Volume flow (standard):

- ±0.5 % o.r. for 0.5 to 10 m/s (1.6 to 33 ft/s)

Volume flow (option):

- ±0.3 % o.r. for 0.5 to 10 m/s (1.6 to 33 ft/s) -

Measuring range

0.5 to 10 m/s (1.6 to 33 ft/s)

-

Medium temperature range

-40 to +150 °C (-40 to +302 °F)

-40 to +200 °C (-40 to +392 °F) optional -

Max. process pressure

PN 40 / ASME Cl. 300 / JIS 20K

-

Wetted materials

Sensor:

A351-CF3M (DN25 to 100)

1.4404/TP316/TP316L or A106 GrB (DN150 to 300)

Transducer: 1.4404/316/316L

Flanges : 1.4404/316/316L or A105/1.0432

Field of application

Prosonic Flow F is the inline sensor with rugged industrial design for Ultrasonic fluid measurement. Combined with the loop-powered Prosonic Flow 92 transmitter, the device offers easy system integration and accuracy at an attractive price. Prosonic Flow 92F is ideally suited for the chemical and petrochemical industries.

The measuring principle is independent of pressure, density, temperature, conductivity and viscosity

Inline device for homogeneous conductive and non-conductive liquids in the chemical and petrochemical industry

Device properties:

Full compliance according to NACE MR0175 and MR0103

Nominal diameter: DN 25 to 300 (1 to 12")

Medium temperature: –40 to 200 °C (–40 to 392 °F)

Device as compact or remote version

2-line backlit display with push buttons

HART, PROFIBUS PA, FOUNDATION Fieldbus

Benefits

Safe design for process industries – international hazardous area approvals

No additional pressure loss – full-bore design

Process transparency – diagnostic capability

Easy installation and reduced installation costs – loop-powered transmitter

Fully industry compliant – IEC/ATEX/FM/CSA/JPN/NEPSI

Automatic recovery of data for servicing

Videos

Extended selection

-

High-end products

- Highly functional and convenient

Technical excellence

Simplicity

-

Standard products

- Reliable, robust and low-maintenance

Technical excellence

Simplicity

-

Specialized products

- Designed for demanding applications

Technical excellence

Simplicity

Variable

| FLEX selections | Technical excellence | Simplicity |

|---|---|---|

Fundamental selection Meet your basic measurement needs |

Technical excellence

|

Simplicity

|

Lean selection Handle your core processes easily |

Technical excellence

|

Simplicity

|

Extended selection Optimize your processes with innovative technologies |

Technical excellence

|

Simplicity

|

Xpert selection Master your most challenging applications |

Technical excellence

|

Simplicity

Variable |

Loading alternative products

Loading alternative products

-

-

Technical Information (TI)

Proline Prosonic Flow 92F Technical Information (SI units)

English version - 11/2010

Ultrasonic Flow Measuring System, 2-Wire loop powered inline, flowmeter

EN 05/11/201004/02/200901/06/2006Language:

English

Version:

05/11/2010

File size:

1.4 MB

File name:

TI00073DEN_1310.pdf

-

-

-

Technical Information (TI)

Proline Prosonic Flow 92F Technical Information (SI units)

Ultrasonic Flow Measuring System, 2-Wire loop powered inline, flowmeter

EN 05/11/201004/02/200901/06/2006Language:

English

Version:

05/11/2010

File size:

1.4 MB

File name:

TI00073DEN_1310.pdf

-

-

-

Operating Instruction (BA)

Proline Prosonic Flow 92F FOUNDATION Fieldbus Operating Instructions

Ultrasonic Flow Measuring System

EN 08/11/201001/02/2008Language:

English

Version:

08/11/2010

File size:

3.3 MB

File name:

BA00128DEN_1310.pdf

-

-

-

Operating Instruction (BA)

Proline Prosonic Flow 92F Operating Instructions

Ultrasonic Flow Measuring System

EN 05/11/201001/06/2006Language:

English

Version:

05/11/2010

File size:

3.5 MB

File name:

BA00121DEN_1310.pdf

-

-

-

Operating Instruction (BA)

Prosonic Flow 92F PROFIBUS PA Operating Instructions

Ultrasonic Flow Measuring System, 2-Wire loop powered inline

flowmeterEN 11/11/201001/06/2006Language:

English

Version:

11/11/2010

File size:

3.6 MB

File name:

BA00122DEN_1310.pdf

-

-

-

Short Instruction (KA)

Proline Prosonic Flow 92F Brief Operating Instructions

Ultrasonic flow measuring system

Two-wire inline flowmeterEN 01/09/2009Language:

English

Version:

01/09/2009

File size:

550.4 KB

File name:

KA038DEN_0909.pdf

-

-

-

Installation Instructions (EA)

Safety Instructions for Spare Parts Installation Instructions

Flowmeter

EN 01/03/201828/11/201325/04/2013Language:

English

Version:

01/03/2018

File size:

139.5 KB

File name:

EA01051DA2_0318.pdf

-

-

-

Installation Instructions (EA)

Replacing cover and O-ring Installation Instructions

romag 10, 23, 50, 51, 53, 55, 400, 800, Promass 40, 80, 83, 84, 8ME,

CNGmass 8FF, LPGmass 8FE, Cubemass 8CM, Prosonic Flow 90, 91,9

2, 93, t-mass 65, Prowirl 72, 73EN 01/10/201828/06/2012Language:

English

Version:

01/10/2018

File size:

520.1 KB

File name:

EA00098DA2_1518.pdf

-

-

-

Installation Instructions (EA)

Repair kit cover remote version Installation Instructions

Promag 10, 50, 51, 53, 55, 400, 800, Promass 80, 83, 84, CNGmass DCI,

Cubemass DCI, Prosonic Flow 92 F, t-mass 65EN 01/10/201813/11/201418/04/2014Language:

English

Version:

01/10/2018

File size:

216.9 KB

File name:

EA01108DA2_0318.pdf

-

-

-

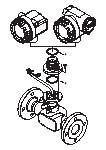

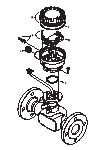

Installation Instructions (EA)

EA Installing sensor parts

Prosonic Flow 92F, Prowirl 72, 73, 200

EN 16/10/202301/09/201714/01/201628/11/2013Language:

English

Version:

16/10/2023

File size:

2 MB

File name:

EA01085DA2_0423-00.pdf

-

-

-

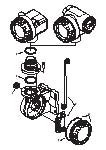

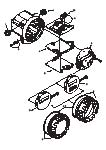

Installation Instructions (EA)

Replacing transmitter parts

Prowirl 72, 73, Prosonic Flow 92

EN 03/03/202001/04/201913/12/2010Language:

English

Version:

03/03/2020

File size:

451.5 KB

File name:

EA00043DA2_1520.pdf

-

%20-%20CS01637X.jpg)