Specs at a glance

-

Max. measurement error

Mass flow (liquid): ±0.15 %

Density (liquid): ±0.0005 g/cm³ -

Measuring range

0 to 18 000 kg/h (0 to 660 lb/min)

-

Medium temperature range

–40 to +125 °C (–40 to +257 °F)

150 °C allowed for 1 h -

Max. process pressure

PN 40

-

Wetted materials

Measuring tube: 1.4539 (904L)

Connection: 1.4404 (316/316L)

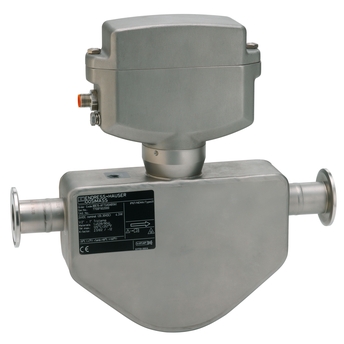

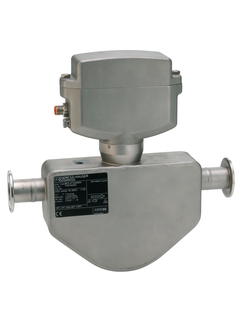

Field of application

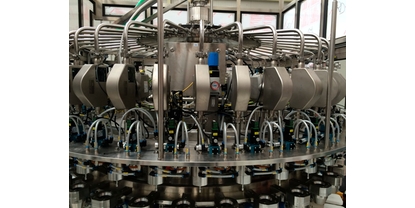

Dosimass is specially designed for filling and bottling applications. It measures volume and mass flow directly with temperature and density compensation to ensure maximum repeatability. Designed for applications where space is a premium, Dosimass will be the preferred choice for system integrators, skid builders and equipment manufacturer.

Measuring principle operates independently of physical fluid properties such as viscosity or density

Measurement of liquids with the most diverse properties in the continuous process control & batching applications.

Device properties

Nominal diameter: DN 8 to 25 (3/8 to 1")

Various hygienic process connections, 3A conform

CIP, SIP cleanable sensor

Robust, ultra-compact transmitter housing

Pulse/frequency/switch output, Modbus RS485

Excellent and easy cleanable transmitter

Benefits

-

High process safety – high measuring accuracy for different media in shortest filling time

-

Fewer process measuring points – multivariable measurement (flow, density, temperature)

-

Space-saving installation – no in/outlet run needs

-

Versatile and time-saving wiring – plug connector

-

Fast commissioning – pre-configured devices

-

Automatic recovery of data for servicing

Videos

Xpert selection

-

Specialized products

- Designed for demanding applications

Technical excellence

Simplicity

Variable

-

Standard products

- Reliable, robust and low-maintenance

Technical excellence

Simplicity

-

Specialized products

- Designed for demanding applications

Technical excellence

Simplicity

Variable

| FLEX selections | Technical excellence | Simplicity |

|---|---|---|

Fundamental selection Meet your basic measurement needs |

Technical excellence

|

Simplicity

|

Lean selection Handle your core processes easily |

Technical excellence

|

Simplicity

|

Extended selection Optimize your processes with innovative technologies |

Technical excellence

|

Simplicity

|

Xpert selection Master your most challenging applications |

Technical excellence

|

Simplicity

Variable |

Loading alternative products

Loading alternative products

-

-

Technical Information (TI)

Dosimass Technical Information

English version - 02/2017

Coriolis flowmeter The compact sensor with an ultra-compact transmitter

EN 01/02/201701/09/201513/08/201401/10/201201/02/2011Language:

English

Version:

01/02/2017

File size:

1.6 MB

File name:

TI00065DEN_1717.pdf

-

-

-

Technical Information (TI)

Dosimass Technical Information

Coriolis flowmeter

The compact sensor with an ultra-compact transmitterEN 01/02/201701/09/201513/08/201401/10/201201/02/2011Language:

English

Version:

01/02/2017

File size:

1.6 MB

File name:

TI00065DEN_1717.pdf

-

-

-

Operating Instruction (BA)

Dosimass Modbus RS485 Operating Instructions

Coriolis flowmeter

EN 31/01/201901/02/201701/09/201513/08/2014Language:

English

Version:

31/01/2019

File size:

1.5 MB

File name:

BA01320DEN_0419.pdf

-

-

-

Operating Instruction (BA)

Dosimass Operating Instructions

Coriolis flowmeter

EN 31/01/201901/02/201701/09/201513/08/201401/10/2012Language:

English

Version:

31/01/2019

File size:

1.4 MB

File name:

BA00097DEN_1819.pdf

-

-

-

Device Parameter (GP)

Dosimass Description of Device Parameters

Coriolis flowmeter

EN 31/01/201901/09/2015Language:

English

Version:

31/01/2019

File size:

690.4 KB

File name:

GP01050DEN_0219.pdf

-

-

-

Device Parameter (GP)

Dosimass Modbus RS485 Description of Device Parameters

Coriolis flowmeter

EN 31/01/201901/09/2015Language:

English

Version:

31/01/2019

File size:

905.3 KB

File name:

GP01047DEN_0219.pdf

-

-

-

Short Instruction (KA)

Dosimass Brief Operating Instructions

Coriolis flowmeter

EN 01/02/201701/09/201513/08/201401/10/201201/02/2011Language:

English

Version:

01/02/2017

File size:

1.1 MB

File name:

KA00043DEN_0517.pdf

-

-

-

Installation Instructions (EA)

Replacing electronics module and small parts Installation Instructions

Dosimass 8BE

EN 15/11/201804/08/2009Language:

English

Version:

15/11/2018

File size:

244 KB

File name:

EA00068DA2_0918.pdf

-

-

-

Installation Instructions (EA)

Adapter RSE8, RSE5, RSE4 Installation Instructions

Proline Dosimass, Dosimag

EN 01/10/201814/04/2014Language:

English

Version:

01/10/2018

File size:

297 KB

File name:

EA01104DA2_0218.pdf

-

-

-

Ex Safety Instruction (XA)

Dosimass ATEX: II3G Ex nA IIC T5 to T1 Gc Safety Instructions

Documentation for hazardous areas

EN 01/02/201701/09/201514/08/201401/10/201201/02/2011Language:

English

Version:

01/02/2017

File size:

297.2 KB

File name:

XA00079DEN_1717.pdf

-

-

-

Special Documentation (SD)

UKCA marking

Flow, density, concentration, viscosity

EN 04/11/202201/10/2021Language:

English

Version:

04/11/2022

File size:

357.4 KB

File name:

SD02752DEN_0222-00.pdf

-

%20-%20CS01637X.jpg)