Smarter flowmeters for filling applications

RONCHI MARIO developed its new filler around Endress+Hauser's new Dosimag and Dosimass flowmeters

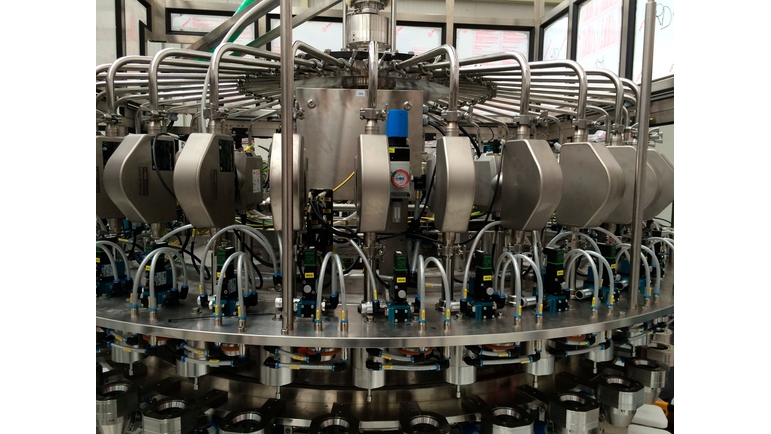

The new filling machine generation of RONCHI MARIO S.p.A. features major innovations. Endress+Hauser's Dosimag and Dosimass flowmeters with integrated batching functionality are key components of the new machine concept. These new flowmeters control the filling process autonomously, providing a constant and outstanding filling performance over time, even under changing conditions. In addition, the new machine design simplifies tasks during operation, service and maintenance.

Real customer value: savings of more than US$ 200 000 p.a.

The improved machine design allows full transparency into the filling process, resulting in an optimized machine control during operation and simplified service and maintenance.

The time for changing fluids or bottle sizes is reduced significantly thanks to the smart algorithm in the Dosimag and Dosimass filling flowmeters. This increases the overall output of the filler.

The improved repeatability of the entire filling machine results in a reduced product give-away due to less overfilling. This saves a leading manufacturer of home care products more than US$ 200 000 annually.

Top filling performance while meeting national regulations

With the latest machine generation RONCHI has targeted to further increase filling performance. The challenge was to reduce the down time required to achieve highest filling performance after product or bottle change (and reduce product loss), while keeping the high filling performance stable, even under changing process conditions. RONCHI also simplified the design to reduce service and maintenance costs. Of course the machine is still meeting national regulations for packaged consumer good.

Intelligent flowmeters with integrated batching function

As a long-term customer of Endress+Hauser, RONCHI was providing valuable input for the design of the new flowmeter generation. RONCHI has designed the new flowmeters in its latest machine right from the beginning. Dosimag and Dosimass provide control functions and a specific filling algorithm allowing the flowmeter to open and close the filling valve. The algorithm compensates automatically the drip quantity after closing of the filling valve even under changing process conditions.

RONCHI MARIO S.p.A.

RONCHI MARIO S.p.A. is a world leader for filling and capping machines. Thanks to 50 years of experience, RONCHI MARIO S.p.A. has acquired a unique know-how and technology level. The company always focuses on innovation to serve its customers with the most performing and flexible machines. RONCHI is highly committed to provide the best packaging solutions for cosmetic, chemical, pharmaceutical and food industries.