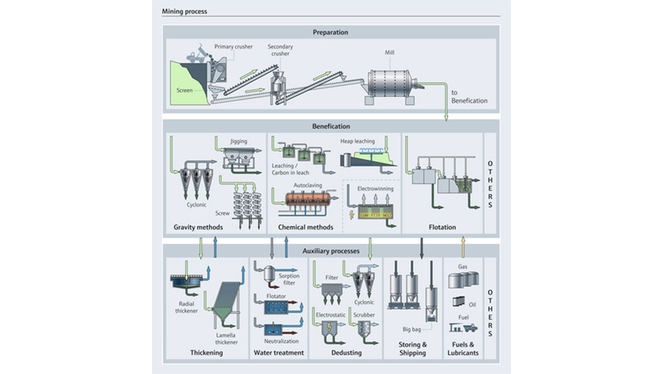

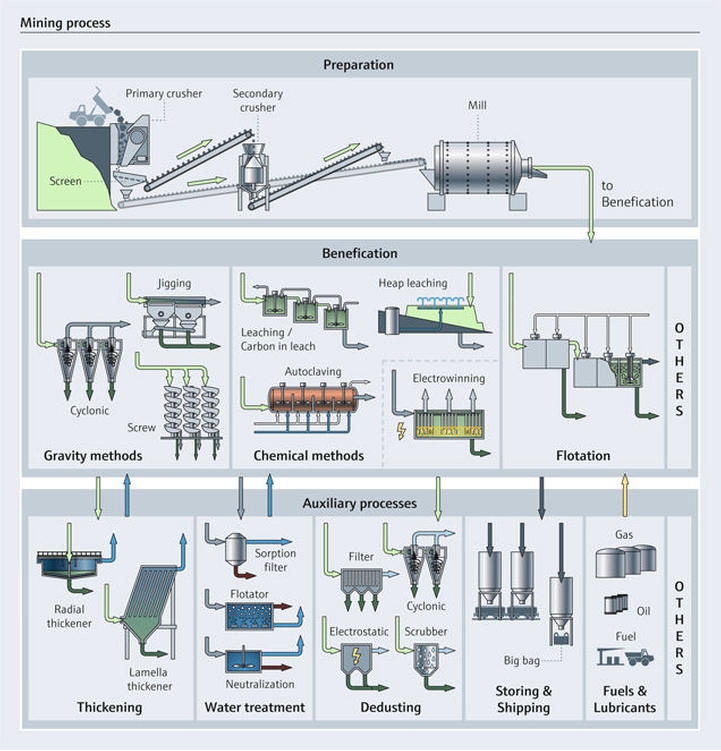

Declining ore grades pose a special challenge for mining operations. Of course there are various processing techniques to get the most out of the raw materials like leaching, thickening and flotation. But naturally they consume energy, chemicals and water. Which means that, to balance out the yield and the costs, the extraction processes must run at an optimum level. Especially in times of volatile markets and prices.

Key facts

35%

productivity loss in mining

That is the result of a study done by the international consulting group McKinsey. They state that mines worldwide lost roughly one third of their productivity in the years 2004-2014.

Learn more about the optimization of mining extraction

Leaching

Leaching is an extraction method that uses acid solutions that are sprayed on crushed ore to generate a pregnant solution with the desired metal. The acids used depend on the type of ore to be leached.

Our expertise in the field

It has been shown that the concentration and the irrigation flow rate of the acid solution has a significant impact on the yield and the acid consumption. Endress+Hauser can offer measuring instruments for parameters that can withstand the aggressive nature of the acids and deliver reliable data.

- Our digital analytical sensors feature non-contact digital data transmission and simple sensor exchange using pre-calibrated sensors reduces process downtime and regular regeneration extends sensor lifetime.

- Our electromagnetic flowmeters are available as both compact or remote version.

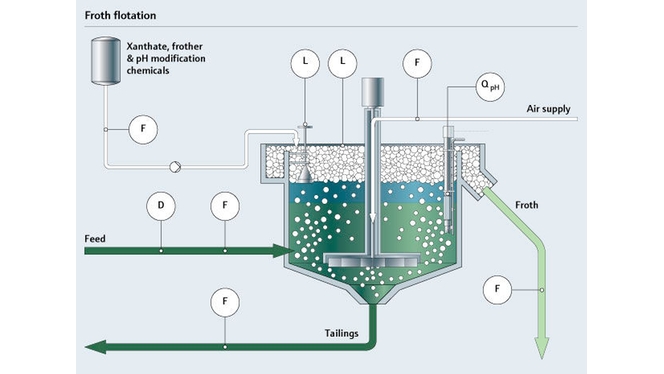

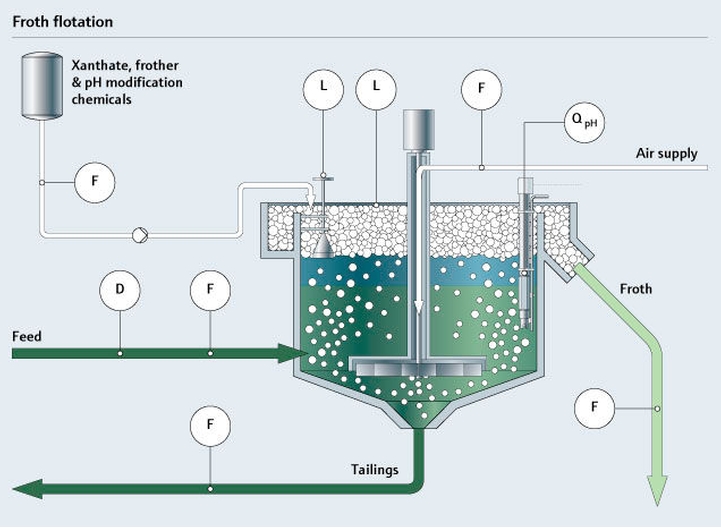

Froth flotation

Flotation is used in various mining processes, such as gold and copper mining, to recover mineral particles which are finer than 500 micron or 35 mesh. Various parameters influence this process and by that your yield. The most important parameters for process efficiency are: flow and density measurement of feedstock, froth height, precise determination of the froth and liquid slurry interface, liquid pH and Eh, dosing and quality of chemical reagents and air flow.

Our expertise in the field

Endress+Hauser not only has instruments for all these tasks but also offers a variety of measuring technologies to ensure you can use the optimum instrument for your process – all from a single source.

- For the measurement of the feedstock, we recommend using an electromagnetic flowmeter with integrated solids content calculation.

- To determine froth height and froth/slurry interface the ideal solution is using two ultrasonic sensors. One measures the distance to the froth, the second sensor measures the distance to a target plate connected to a rod and a conical float..

- Our digital analytical sensors for pH and Eh measure reliably even in harsh environments.

- The dry solids content, the feed rate and the froth height can be used as a feed forward signal for the xanthate, frother and pH modification chemical dosing control loop. Our Coriolis flowmeter can input these parameters and enable accurate dosing.

- Air is used in flotation for agitation. By measuring the air flow the costs for creating compressed air can be optimized. Our vortex flowmeter is not affected by plant vibration or air hammers, and offers high accuracy and a wide measuring range.

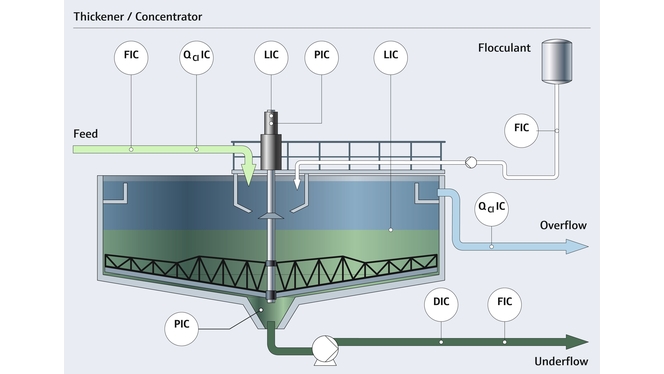

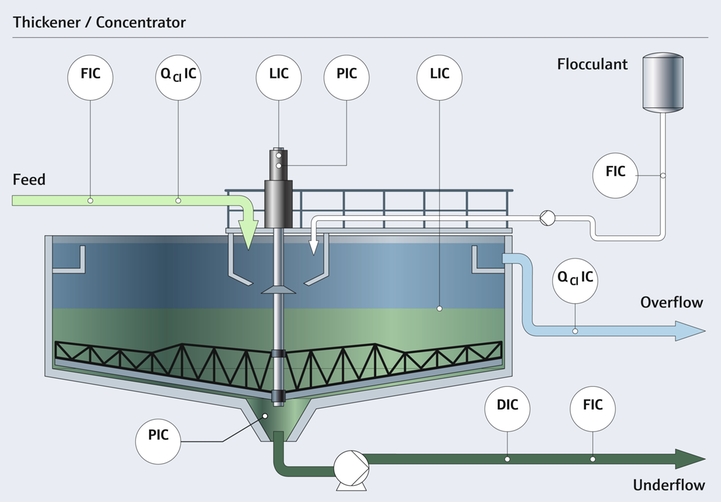

Thickener

Thickening is a mineral concentration process based on gravity settling. Solids settle on the tank bottom, a process which is accelerated by the addition of flocculent.

Our expertise in the field

Important indicators are bed level, bed mass, underflow density and flow to calculate the total slurry volume, and overflow clarity for final quality assurance. By measuring all these parameters, operators can make the whole process more efficient and safer by reducing the risk of tank overflow.

- Measuring the bed level is one o f the most important parameters for this process. It is ideally measured using submersible sonar technology. Depending on the bed level, the dosing of the flocculent - measured with a flowmeter - can be optimized.

- Bed mass in the thickener is measured with an abrasion-resistant pressure device,

- To measure density in the underflow we recommend using either a radiometric density measurement device or an electromagnetic flow sensor with integrated solids content calculation.

- With a turbidity sensor the clarity of the overflow and by that the overall quality of the thickening can be controlled.

Benefits

Whatever challenges you face with your extraction processes - be it low yields, high OPEX or expensive maintenance routines - thanks to the in-depth industry expertise of our consultants they know exactly how to improve your processes. Together with our customers they have achieved remarkable results during the past 60 years - thanks also to our industry-optimized instrumentation portfolio.

Key facts

50%

reduction of chemicals used.

Key facts

90%

reduction of hours spend on maintenance possible.

Key facts

10 million

devices installed worldwide

How we can help

Leaching, flotation and thickening are fundamental steps in modern mining separation processes. Achieving an optimal separation however is a complex task due to the many interconnected variables. All three processes use chemicals which are one of the main cost drivers. And they consume also a lot of water, which in some mining regions can be a very scarce resource, which the plants first have to produce through processes like desalination of salt water for example.

- Leaching

- Froth flotation

- Thickening