Time saved, safety increased

At Returkraft, SIL proof tests of pressure transmitters are handled with simplicity

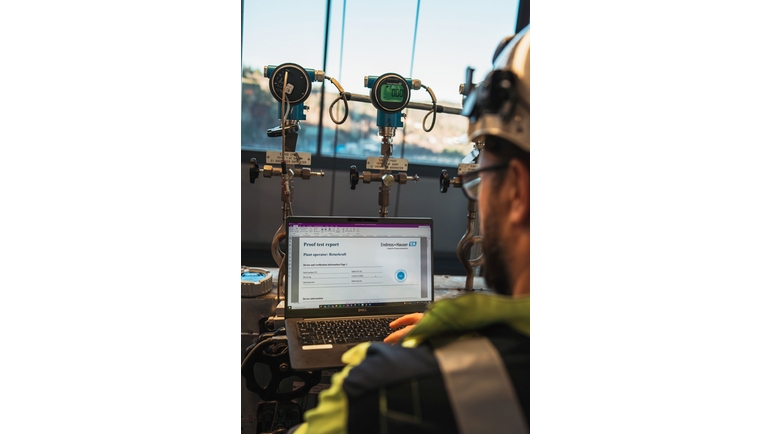

Employees of Returkraft regularly have to fulfill and document all requirements of the SIL measuring points in the plant. With the Endress+Hauser pressure gauges, they are able to save time while completing their tasks without compromising safety.

The results

-

Time savings and reduced effort for SIL-proof tests

-

Commissioning of the devices is done quickly and safely

-

Risks of systematic failures are minimized

Customer challenge

In Returkraft’s incinerator, the pressure conditions must be monitored continuously and precisely. A critical point in this respect is the extraction of the flue gases from the furnace. For this reason, monitoring of the pressure is highly relevant to safety and thus part of the Safety Integrity Level (SIL) in plants of this type. The risk from systematic failures such as operating errors, leakage currents, or clogged impulse lines must be minimized as far as possible.

Our solution

For flue gas measurement, Returkraft relies on the Cerabar PMC71B pressure transmitter from Endress+Hauser. Its robust and abrasion-resistant ceramic measuring diaphragm allows even the smallest pressures to be determined with high precision and reliability. Thanks to innovative functions, Returkraftemployees save time and effort, while at the same time increasing safety:

A commissioning assistant, the so-called Wizard, guides them through the menu.

A SIL Wizard allows to double-checking the settings of all safety-relevant parameters.

Thanks to the CRC checksum, the user can quickly check whether safety-relevant parameters have been unintentionally adjusted.

The Wizards can be executed with a smartphone or centrally from the control room.

-

Standard products

- Reliable, robust and low-maintenance

Technical excellence

Simplicity

-

Specialized products

- Designed for demanding applications

Technical excellence

Simplicity

Variable

| FLEX selections | Technical excellence | Simplicity |

|---|---|---|

Fundamental selection Meet your basic measurement needs |

Technical excellence

|

Simplicity

|

Lean selection Handle your core processes easily |

Technical excellence

|

Simplicity

|

Extended selection Optimize your processes with innovative technologies |

Technical excellence

|

Simplicity

|

Xpert selection Master your most challenging applications |

Technical excellence

|

Simplicity

Variable |