Specs at a glance

-

Accuracy

class 2 acc. to IEC 60584

ASTM E230 and ANSI MC 96.1

IEC/Class A

IEC/Class AA -

Response time

depending on configuration:

TC:

t50 = 2 s

t90 = 5 s

RTD:

t50 = 0,8s

t90 = 2s -

Max. process pressure (static)

at 20 °C: 200 bar (2900 psi)

-

Operating temperature range

Type K:

max. 1.150 °C

(max. 2.102 °F)

Type J:

max. 720 °C

(max. 1.328 °F)

Type N:

max. 1.100 °C

(max. 2.012 °F)

Pt100 WW; 3mm; 316L; -200...600oC

Pt100 WW; 6mm; 316L; -200...600oC

Pt100 TF; 3mm; 316L; -50…400oC

Pt100 TF; 6mm; 316L; -50…400oC

Pt100 StrongSens; 6mm; 316L; -50…500oC -

Max. immersion length on request

up to 30.000,00 mm (1181'')

Field of application

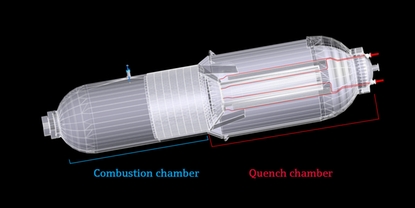

The iTHERM TMS02 MultiSens Flex can be customized for various applications: Bendable into a 3D layout, it provides a complete temperature profile using only a single process connection. The device is configurable with or without thermowells for optimal response times, mechanical strength or sensors replaceability. It is available with either TC/RTD technology or with our iTHERM StrongSens and features an advanced diagnostics chamber for additional safety.

Petrochemical industry

Heavy Chemical processes

Benefits

-

Infinite layouts of 3D sensors distribution for any desired process monitoring configuration

-

High degree of customization thanks to a modular product design for easy installation, process integration and maintenance

-

High degree of insert process compatibility as per standard IEC 60584, ASTM E230 and IEC 60751

-

On-board electronic heat protection for highest product durability

-

Compliance to different types of protection for use in hazardous locations for easy process integration

-

Diagnostic chamber as secondary process barrier for additional safety, capable of pressure monitoring for predictive maintenance through advanced diagnostics

Videos

Xpert selection

-

Specialized products

- Designed for demanding applications

Technical excellence

Simplicity

Variable

-

Standard products

- Reliable, robust and low-maintenance

Technical excellence

Simplicity

-

Specialized products

- Designed for demanding applications

Technical excellence

Simplicity

Variable

| FLEX selections | Technical excellence | Simplicity |

|---|---|---|

Fundamental selection Meet your basic measurement needs |

Technical excellence

|

Simplicity

|

Lean selection Handle your core processes easily |

Technical excellence

|

Simplicity

|

Extended selection Optimize your processes with innovative technologies |

Technical excellence

|

Simplicity

|

Xpert selection Master your most challenging applications |

Technical excellence

|

Simplicity

Variable |

Loading alternative products

Loading alternative products

-

-

Technical Information (TI)

TI iTHERM MultiSens Flex TMS02 Multipoint thermometer

Direct-contact RTD/TC multipoint thermometer for 3D temperature profiling, with flexible sensors and a diagnostics chamber for appli

cations in the oil, gas, and petrochemical industriesEN 27/01/202529/09/202324/12/201813/11/2017Language:

English

Version:

27/01/2025

File size:

4.5 MB

File name:

TI01361TEN_0425-00.pdf

-

-

-

Technical Information (TI)

TI iTHERM ProfileSens TS901

Patented multipoint temperature cable probe for oil & gas and

petrochemical applications. To be used as an insert in multipoint ther

mometers, such as MultiSens Flex TMS0x.EN 29/09/202303/05/2019Language:

English

Version:

29/09/2023

File size:

9.8 MB

File name:

TI01346TEN_0223-00.pdf

-

-

-

Operating Instruction (BA)

BA iTHERM MultiSens Flex TMS02

Modular direct contact TC and RTD multipoint thermometer for direct contact with the medium or with a shared or individual thermowel

lEN 26/03/202529/09/202324/12/201813/11/2017Language:

English

Version:

26/03/2025

File size:

3.9 MB

File name:

BA01598TEN_0425-00.pdf

-

-

-

Ex Safety Instruction (XA)

iTHERM MultiSens Flex TMS02

Ex ia IIC T1...T6 Ga

EN 27/06/2022Language:

English

Version:

27/06/2022

File size:

519.5 KB

File name:

XA02891TEN_0122-00.pdf

-

-

-

Ex Safety Instruction (XA)

XA iTHERM MultiSens Flex TMS02

ATEX/IECEx:

Ex ia IIC T6...T1 Ga

Ex ia IIC T6...T1 Ga/Gb

Ex ia IIIC T85°C...T450°C Da/Db

Ex ia/db IIC T6...T1 Ga/Gb

Ex ia/tb IIIC T85°C...T450°C Da/DbEN 28/11/2025Language:

English

Version:

28/11/2025

File size:

612.6 KB

File name:

XA03680TEN_0125-00.pdf

-

-

-

Ex Safety Instruction (XA)

XA iTHERM MultiSens Flex TMS02

ATEX/IECEx:

Ex ta/tb IIIC T85°C...T450°C Da/Db

Ex db IIC T6...T1 Ga/Gb

Ex ta/tb IIIC T85°C...T450°C Da/DbEN 28/11/2025Language:

English

Version:

28/11/2025

File size:

584.7 KB

File name:

XA03681TEN_0125-00.pdf

-

-

-

Special Documentation (SD)

Device viewer

Technical documentation in other languages

Language:

English

Version:

14/07/2021

File size:

478.5 KB

File name:

SD02429R09EN_0121.pdf

-

-

-

PU (Publication)

iTHERM MultiSens Flex TMS01, TMS02

Multipoint-Thermometerfamilie

Language:

German

Version:

17/09/2018

File size:

2.9 MB

File name:

PU01236T09DE_0322_TMS0x.pdf

-

-

-

Competence Brochure (CP)

Kompetenzbroschüre Erstellung von Temperaturprofilen Vorgefertigte Lösungen für die Öl- und Gasindustrie und die petroch emische Industrie

Kompetenzbroschüre

Erstellung von Temperaturprofilen

Vorgefertigte Lösungen für die Öl- und Gasindustrie und die

petroch

emische IndustrieLanguage:

German

Version:

06/07/2023

File size:

38.5 MB

File name:

CP00003TDE_0523.pdf

-

-

-

Competence Brochure (CP)

Competence brochure Temperature Profiling Pre-engineered solutions for the oil & gas, petrochemical industries

Competence brochure

Temperature profiling

Pre-engineered solutions for the oil & gas,

petrochemical and chemical industr

iesLanguage:

English

Version:

06/07/2023

File size:

39 MB

File name:

CP00003TEN_0523.pdf

-